Keg coupler, All

How to use A System Keg Coupler?

The keg coupler is a vital tool in the world of beer dispensing, allowing for efficient and convenient tapping of kegs. Whether you are a professional bartender or an avid homebrewer, understanding how to use the A System keg coupler is essential for a seamless beer serving experience. In this comprehensive guide, we will delve into the origin of the A System keg coupler, explore its components and features, provide a step-by-step usage tutorial, offer troubleshooting tips, highlight safety precautions, examine different applications and variations, and conclude with recommendations for optimal usage. By the end, you will have a complete understanding of the A System keg coupler and be equipped with the knowledge to make the most of this indispensable beer dispensing tool.

Introduction to A System Keg Coupler

What is a Keg Coupler?

Ah, the keg coupler. The unsung hero of the beer world. If you’ve ever been to a party or a bar, chances are you’ve seen one of these handy devices in action. But what exactly is a keg coupler?

In simple terms, a keg coupler is a tool used to connect a keg to a beer dispensing system. It’s like the middleman between the keg and your glass, ensuring a smooth flow of delicious golden nectar. Without a keg coupler, you’d be left with a keg of beer but no way to get it out. And that would be a tragedy of epic proportions. read more..

Importance of Using a Keg Coupler

Now, you might be thinking, “Can’t I just drink straight from the keg like a true barbarian?” Well, technically you could, but it wouldn’t be the most efficient or enjoyable way to enjoy your favorite brew.

Using a keg coupler not only allows for easy dispensing of beer, but it also helps maintain the carbonation and freshness of the beer. It ensures that the pressure inside the keg is regulated, preventing excessive foaming or flat beer disasters. Plus, it’s a lot more civilized than chugging straight from the tap. Trust me, your friends will thank you.

Historical Background of Keg Couplers

Now let’s take a little trip back in time to explore the fascinating history of keg couplers. Kegs have been around for centuries, and it was only a matter of time before someone came up with a genius way to tap into them.

The first keg couplers were invented in the late 19th century, revolutionizing the way beer was served. Before that, it was a messy and labor-intensive process that involved hammering a tap into the keg. Not exactly ideal for a quick and easy pour.

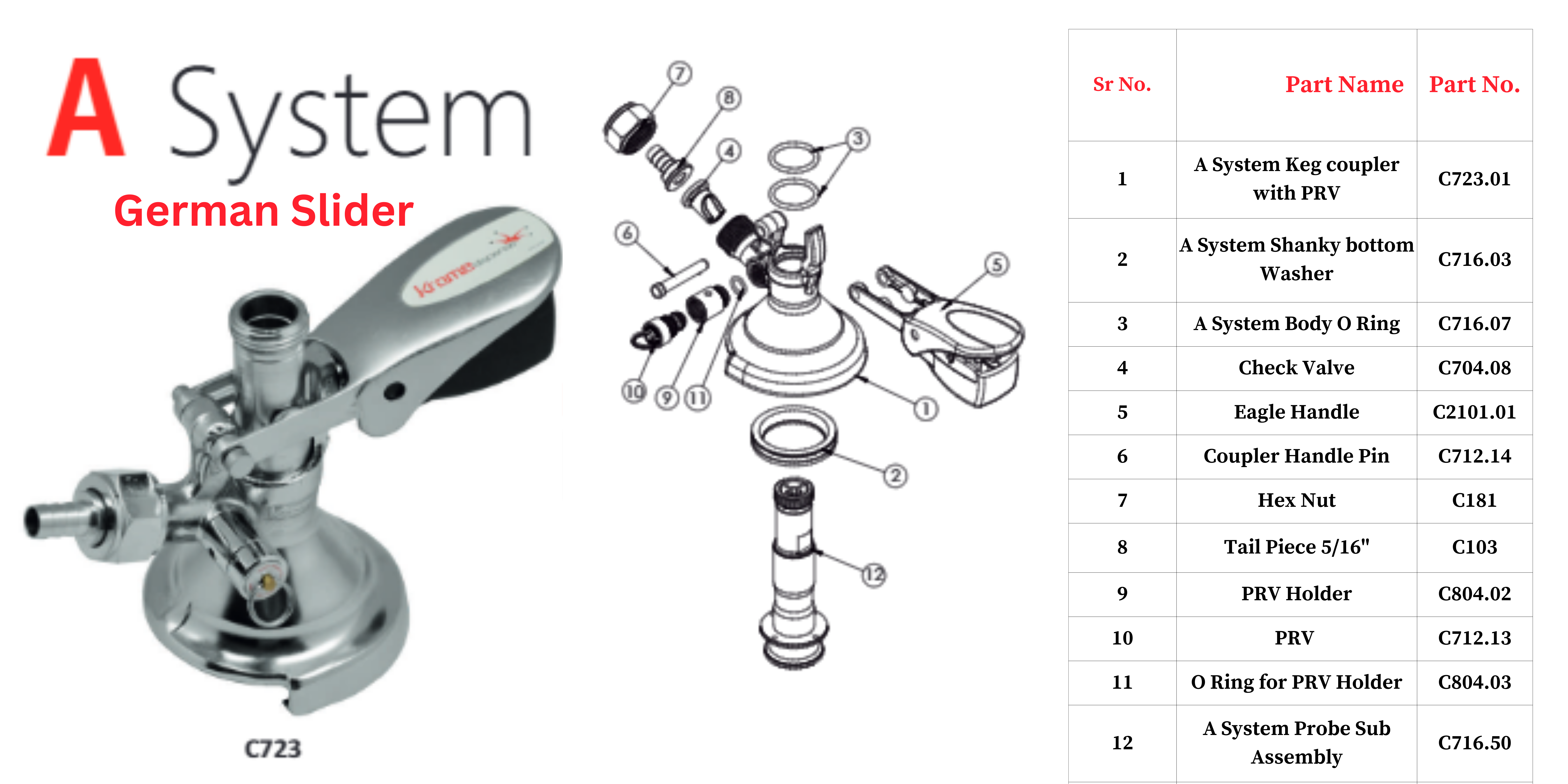

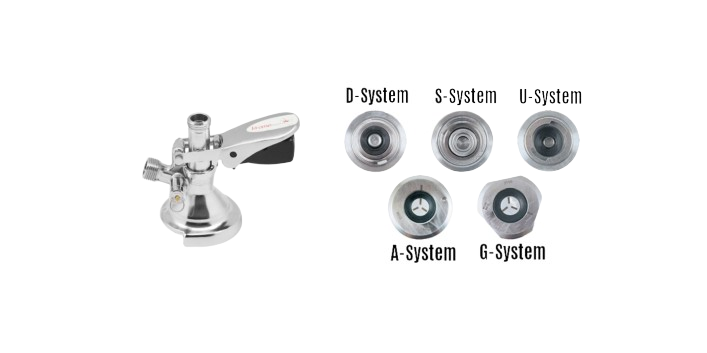

Evolution of A System Keg Coupler

Fast forward to today, and we have a wide variety of keg couplers to choose from. One popular type is the A System keg coupler, which is commonly used for beers originating from Germany, Austria, and certain parts of Europe.

The A System keg coupler has undergone its fair share of improvements and refinements over the years. With its standardized design, it ensures compatibility with A System kegs, making it a breeze to set up and start pouring your favorite German brews.

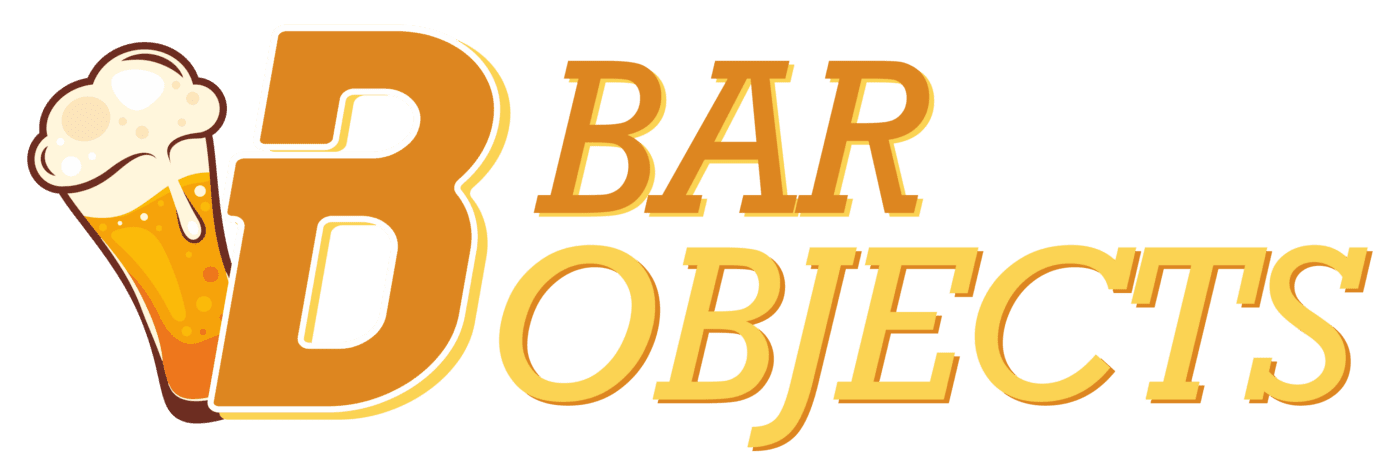

Components and Features of A System Keg Coupler

Overview of the Main Components

Alright, let’s get down to the nitty-gritty of what makes up an A System keg coupler. It consists of several key components working together to deliver that ice-cold beer straight to your glass.

The main components include a probe, a coupler body, a handle, a check valve, and a pressure relief valve. Each part plays a crucial role in the smooth operation of the keg coupler. Think of them as the Avengers of the beer world, each with their unique powers but coming together for the greater good.

Key Features and Functionalities

Aside from the basic components, the A System keg coupler comes with some cool features that elevate it to superhero status. It usually has a 5/8″ gas inlet, a 3/8″ product outlet, and a pressure relief valve for safety purposes.

Some keg couplers even come with a built-in shut-off valve, allowing you to control the flow of beer with precision. It’s like having a personal beer sommelier right at your fingertips. Fancy, huh?

Step-by-Step Guide on How to Use A System Keg Coupler

1 Preparing the Keg for Coupler Attachment

First things first, you’ll want to make sure your keg is properly chilled and ready to party. No warm beer allowed here. Once your keg is chilled to perfection, remove the protective cap or cover from the keg valve.

2 Attaching the A System Keg Coupler

Take your A System keg coupler and align it with the valve on the keg. Make sure to push it firmly and give it a clockwise twist to ensure a secure connection. You’ll hear a satisfying click when it’s properly attached.

3 Dispensing Beer Using the Keg Coupler

Now comes the fun part—dispensing that liquid gold. Grab a glass and open the faucet by pulling the handle forward. Adjust the angle and speed of the pour to achieve that perfect head-to-beer ratio. And voila! You’re officially a keg coupler pro.

Remember to always handle kegs and keg couplers with care, and drink responsibly. Cheers to the magic of the A System keg coupler and the joy it brings to beer lovers everywhere!

Troubleshooting and Maintenance Tips for A System Keg Coupler

Common Issues and How to Troubleshoot Them

Ah, the joys of troubleshooting. Even the most well-designed A System keg coupler can run into a few hiccups along the way. Here are some common issues you might encounter and how to give them a swift kick in the keg:

– Foam Party: If your beer is pouring out more foam than liquid gold, it’s likely a temperature or pressure issue. Check that your keg is properly cooled and that the pressure is set within the recommended range. A little adjustment here and there should have you pouring perfect pints in no time.

– Leaky Faucet: No one likes a drippy tap. If you notice your keg coupler is leaking where it connects to the faucet, check for loose fittings or worn out rubber seals that might need replacing. And don’t forget to tighten everything up snugly, but not Hulk-level tight.

– Stuck Tap: When the tap is stuck in the on or off position, it can put a real damper on your keg party plans. Try applying a little lubricant to the moving parts and gently twisting or jiggling the tap to loosen it up. Just remember, we’re talking about taps here, not dance moves.

Safety Precautions When Using A System Keg Coupler

Handling Pressurized Systems Safely

When it comes to pressurized systems, safety should always be your top priority. Here’s how to keep yourself and your kegs out of harm’s way:

– Gentle Touch: When connecting or disconnecting the keg coupler, handle it with care. Sudden movements or mishandling can cause a sudden release of pressure, resulting in a beer explosion that no one wants to witness (or clean up).

– Protect Your Eyes: It’s always a good idea to wear protective eyewear when working with pressurized keg systems. A rogue burst of carbonation to the eyeball is nobody’s idea of a good time.

Important Safety Tips for Keg Coupler Usage

Working with a keg coupler may not be rocket science, but it’s still essential to follow these safety guidelines:

– No Monkey Business: Avoid using excessive force when attaching or detaching the coupler. Remember, a gentle touch is all it takes.

– Keep It Cool: Before connecting or disconnecting the coupler, make sure the keg’s pressure has been fully released. Attempting to disengage a pressurized keg is like removing a tightly-wedged cork from a champagne bottle – it’s a recipe for mess and potentially dangerous situations.

Exploring Different Applications and Variations of A System Keg Coupler

Commercial Uses of A System Keg Coupler

A System keg couplers are the workhorses of the commercial beer industry. They are commonly used in bars, restaurants, and breweries, ensuring that delicious brews flow freely from kegs to tap handles. So the next time you enjoy a pint at your favorite watering hole, take a moment to appreciate the trusty A System keg coupler making it all possible.

Homebrewing Applications and Adaptations

Who said keg couplers were only for the pros? Homebrewing enthusiasts can also take advantage of the A System keg coupler’s versatility. With the right equipment and setup, you can turn your garage or kitchen into a mini brewery. Just remember to share the fruits of your labor with friends and loved ones – it’s good for the soul.

Summary of Key Points Discussed

We’ve covered a lot of ground, so let’s recap the key takeaways:

– Troubleshooting and Maintenance: Foam issues? Leaky faucets? We’ve got the troubleshooting tips to make your keg coupler sing again. Keep your coupler clean, check those o-rings, and give that tap handle a little love.

– Safety First: Handling pressurized systems can be tricky, so take precautions and protect your eyes. And please, no gorilla-style twisting of the coupler.

– Exploring Applications: A System keg couplers are the go-to for commercial use, and even homebrewing enthusiasts can get in on the action.

Tips for Optimal Performance and Longevity

To keep your A System keg coupler pouring smoothly for years to come, remember these tips:

– Clean regularly to prevent buildup and maintain the flavor of your brew.

– Check and replace o-rings when necessary to prevent leaks.

– Handle with care when connecting and disconnecting to avoid beer explosions or injuries.

Now, armed with the knowledge of troubleshooting, maintenance, safety, and exploration, go forth and conquer the keg coupler world. Cheers!

FAQ

It is important to identify the specific keg type before selecting a keg coupler. The A System keg coupler is designed to fit kegs that use the A System valve, which is commonly used by breweries such as Grolsch, Heineken, and Amstel. To ensure compatibility, check the markings on your keg or consult the manufacturer’s guidelines.

No, the A System keg coupler is specifically designed for kegs with A System valves. Attempting to use it with other keg types may result in incompatible fittings and improper dispensing. It is crucial to use the correct keg coupler for each keg type to ensure a proper and safe beer pouring experience.

Regular cleaning and maintenance of your A System keg coupler are essential for optimal performance and longevity. It is recommended to clean the coupler after each keg is emptied to prevent the buildup of beer residue and bacteria. Additionally, check for any worn or damaged parts and replace them as needed to ensure smooth operation.

Absolutely. When using an A System keg coupler, it is important to handle pressurized systems with care. Always relieve the pressure in the keg before attempting to remove or attach the coupler. Additionally, make sure to follow proper safety guidelines, wear protective gear if necessary, and be cautious of sharp edges or potential hazards during the handling process.

Carlsberg

Ayinger Altbairisch Dunkel

Ayinger Bräu-Hell

Ayinger Bräu-Weisse

Ayinger Celebrator

Ayinger Frühlingsbier (Springtime Beer)

Ayinger Jahrhundert-Bier

Ayinger Kirta-Halbe (Pint of Country Fair)

Ayinger Liebhard’s Kellerbier

Ayinger Premium-Pils

Ayinger Ur-Weisse (Traditional Wheat)

Ayinger Winter-Bock (Winter “Buck” Beer)

Bavik Pilsner

BayHawk Amber Ale

Bitburger Pilsner

Blanche De Brussels-Bier

Bofferding

Chimay

Cuvee Meilleurs Voeux

De Dolle Arabier

De Dolle Special Extra Export Stout

De Dolle Stille Nacht

De Dolle Teve

Fischer

Franziskaner Hefe-Weisse

Hacker-Pschorr Weisse

Hoegaarden White

Houblon Chouffe IPA Tripel

Isenbeck

JW Lee’s Chouffe

Krombacher

Kronenbourg 1664

La Chouffe

La Gnomette

Löwenbräu Original Lager

McChouffe

N’Ice Chouffe

Palm

Paulaner Hefeweizen

Paulaner Lager

Paulaner Pilsner

Paulaner Salvator

Samuel Smith

Shmaltz Brewing Hebrew Lenny’s R.I.P.

Spaten Lager

Spaten Oktoberfest

Spaten Optimator

Spaten Pils

Staropramen Premium Lager

Starpramen Dark

Starpramen Granat

Steam Whistle

Victoria Bitter

Warsteiner Dunkel

Warsteiner Pils

Weihenstephan Hefe-Weissbier

Weihenstephan Hefe-Weissbier Dunkel

Weihenstephan Korbinian

Weihenstephan Original Lager

At BAR OBJECTS, we aim to uphold a comprehensive database of draft beer brands and their corresponding valve systems used in kegs. However, due to the vast array of breweries and beer brands, it’s not feasible to have an exhaustive listing. Our information is based on data shared by breweries and is subject to change.