What is soda regulator

Carbon Dioxide regulators or Soda Regulators are gas cylinder regulators that control the amount of Co2 dispensed for various applications.

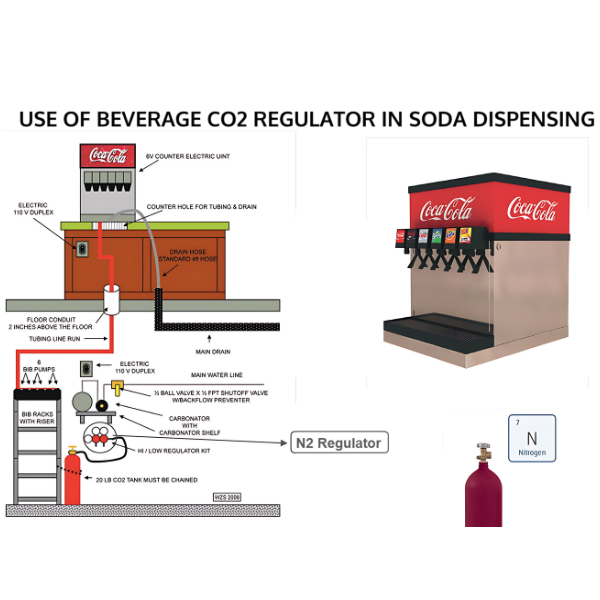

CO2 regulators allow you to “step down” the pressure going to your carbonator and syrup pumps. Primary regulators are usually set to 100 PSI and supply the carbonator, while secondary regulators reduce the CO2 pressure again (usually to 50 PSI) to supply the syrup pumps.

Use of Beverage Co2 Regulator in Soda Dispensing

The role of carbon dioxide that dissolves in water is that it reacts and forms carbonic acid. This carbonic acid cause a fizz in cold drinks. This gas form tiny bubbles and it also serves as a protective measure that keeps soft drink fresh and prevents the growth of bacteria.

Carbon Dioxide regulators are gas cylinder regulators that control the amount of Co2 dispensed for various applications. Some CO2 regulators have flow restrictors that ensure delivery of the gas at a constant rate.

What is the CO2 pressure setting for soda?

If your soda is flat :Check your CO2 Tanks and CO2 Cylinders. The CO2 Regulator (left gauge) on a full tank should read between 700 – 900, with an outgoing pressure (middle / right gauge) between 100- 110.

Soda machine regulators, commonly referred to as CO2 regulators or carbon dioxide regulators, play a crucial role in the operation of soda fountain machines found in restaurants, cafes, and convenience stores worldwide. These regulators control the flow and pressure of carbon dioxide gas, which is essential for carbonating beverages like sodas and sparkling water.

In the realm of beverage dispensing, soda fountain machine regulators ensure consistent carbonation levels and optimal beverage quality. They maintain the precise balance of CO2 gas required to produce the desired fizziness and taste in each drink. These regulators are meticulously calibrated to meet the specific requirements of different beverages, ensuring that customers enjoy a refreshing and satisfying experience with every sip.

Major beverage companies such as Pepsi and Coke also rely on specialized regulators for their soda vending machines, with Pepsi fountain machine regulators and Coke fountain machine regulators ensuring consistent carbonation levels and optimal beverage quality. These regulators, tailored to the unique needs of each brand’s beverages, ensure that the iconic flavors remain consistent across various dispensing locations.

Whether it’s a small countertop soda fountain or a large-scale vending machine, the performance of these regulators directly impacts customer satisfaction and business success. By maintaining optimal carbonation levels and beverage quality, soda machine regulators play a vital role in delivering the refreshing taste that consumers expect from their favorite sodas and carbonated

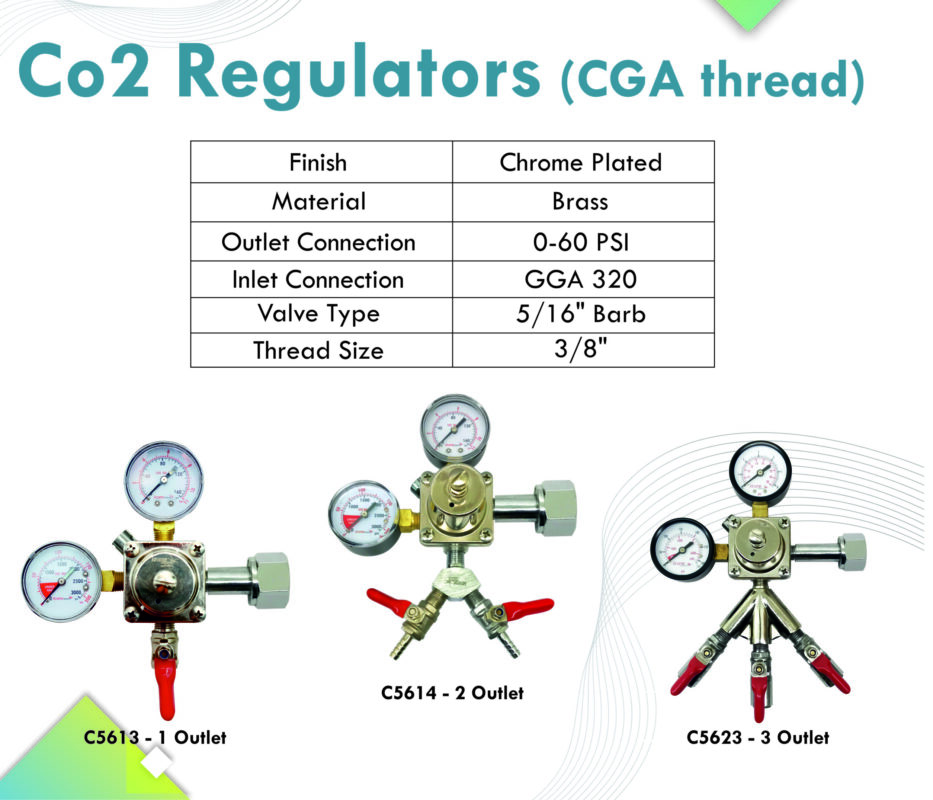

Precision plus Co2 Regulator

- The Precision Plus CO2 Regulator is designed to decrease the gas cylinders high pressure to a lower, usable pressure for dispensing

- Comes with a precision diaphragm for more accurate adjustment

- Also be used on a range of different gasses including: CO2, Oxygen, Argon and Helium

Difference between Primary and Secondary Regulators

Primary Regulators

Primary gas regulator drop the high pressure of gas cylinder to suitable pressure for dispensing. It can be used for single application with single pressure

Secondary Regulators

Secondary gas regulator minimize the pressure from primary regulator or gas blender and distribute the lower pressure to each beer keg.

Precision Plus Secondary Inline CO2 Regulator

- Regulator comes with 1 outlet.

- Control the CO2 flow to a single keg in your draft beer system safely and effectively.

- Apply a lower pressure to each individual keg after lowering the pressure applied by a primary regulator or gas mixer

- Check the amount of gas flowing from the gas source to the keg